History of Precision Fermentation

Fermentation played an essential role in our evolution

Precision Fermentation will play a crucial role in our future

Fermentation is an ancient process, tightly bound with the human story

Humans have been fermenting for thousands of years to make all kinds of foods that we eat every day.

Foods such as bread, yogurt, vinegar, tofu and pickles, and drinks such as beer and wine are all made using fermentation. In nature, microbes carry out fermentation all the time.

Fermentation allowed our ancestors to store and save their food in a way that they had never been able to before

Rather than an endless daily effort to hunt, forage and survive, humans were able to store, prepare and collaborate.

Fermentation is woven deep into the human story, and allowed us to transition away from foraging to storing our food. We no longer had to work as hard to get the energy we needed, and could refocus our activities on developing our skills and tools. Fermentation helped us to evolve.

Fermentation is simply the breakdown of an organic substance—usually sugar—by a microbe

Fermentation can create proteins, enzymes or fats, depending on the genetic properties of the microbe itself.

Fermentation can preserve foods for much longer than they would last in their natural form.

Precision Fermentation (PF) is simply the next step in our understanding

In the last 100 years, we've harnessed our understanding of this ancient technique to create PF

Scientists have learnt to produce vitamins, medications, solvents, organics, acids and even industrial enzymes through PF.

Precision Fermentation is the evolution of our understanding of Fermentation.

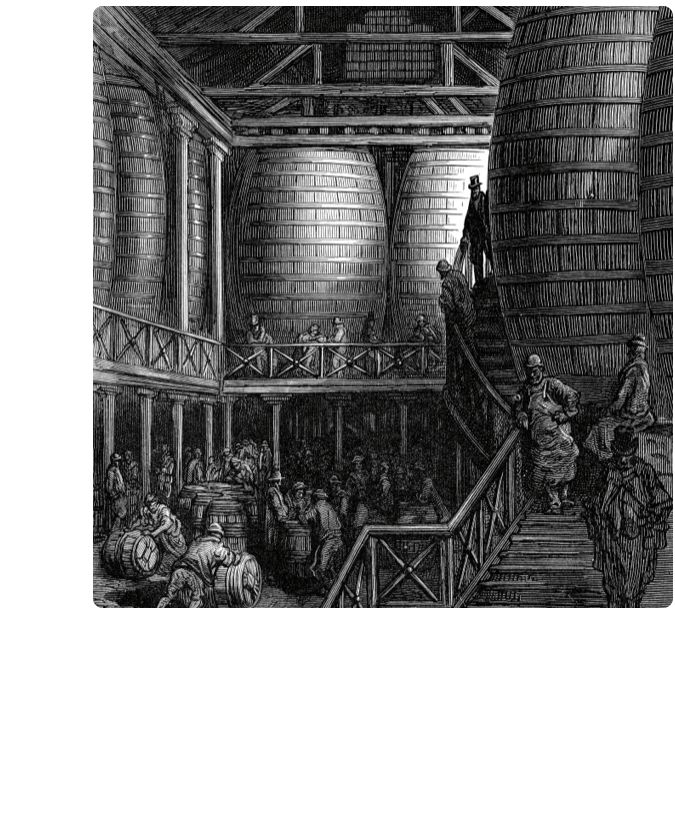

History of fermentation

The term 'industrial fermentation' refers to the time in our history when fermentation began to play a large role in industries all over the world.

In the 20th century, producers started altering microbes in large quantities and in the right conditions to produce complex organic molecules through fermentation.

Many familiar products we use today were produced in this way. Ethanol for alcoholic drinks or fuel, n-butanol for rubber production, penicillin for treating infections, citric acid as a disinfectant or for flavoring, amino acids like the flavoring agent MSG and vitamins we take every day, such as C, B2, B12 and D2—are all available to us because of industrial fermentation.

The addition of precision biology to the industrial fermentation process allowed for PF

This technological advancement has allowed us to create all kinds of products.

We can now engineer the genes of the microbes during the fermentation process to produce incredibly accurate results. Today we can produce industrially fermented molecules faster, cheaper and using fewer resources than ever before.

Initially, high costs meant PF was used primarily in the pharmaceuticals industry

The first PF product on the market was human insulin in the early 1980s.

This was quickly followed by several more PF drugs, including human growth hormone, the hepatitis B vaccine and human erythropoietin (a hormone originating in the kidney). Another group of PF drugs known as biologics came after that to treat conditions such as anemia, AIDS, hepatitis C, multiple sclerosis and certain cancers.

In recent times, the costs of these drugs have become even cheaper.

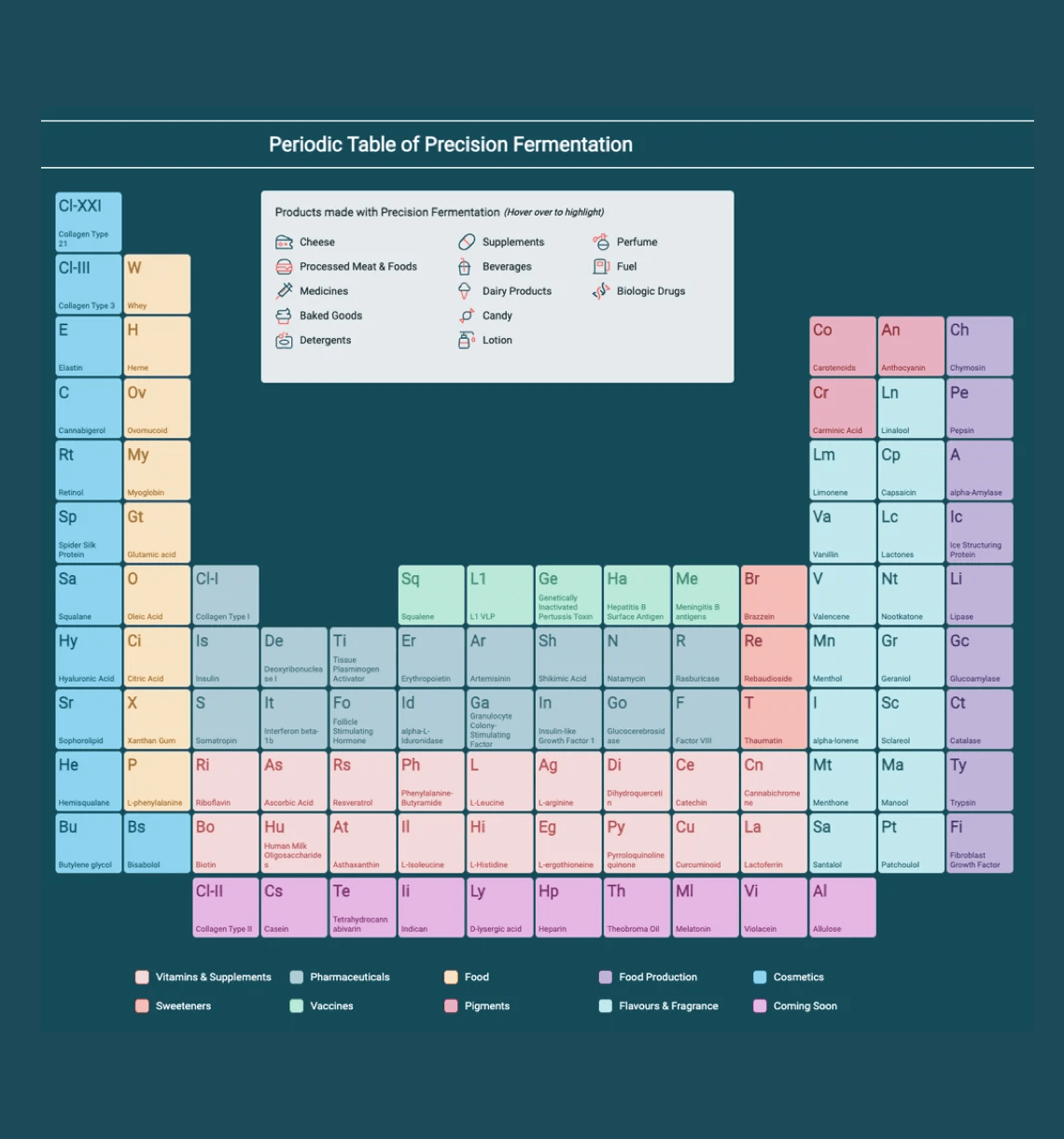

How are PF products used today, and how can they be used in the future?

PF products have begun to be used in food and other reasonably priced goods already at market.

The ingredients made using Precision Fermentation usually have a specific purpose in mind: it could be to improve the smell or taste of a product, or to enhance a products structural or medicinal properties.

Ingredients made using Precision Fermentation increase the quality of the final product, while only making up a small portion of it.

We have the potential to make any protein imaginable!

Proteins are the most common molecules made using PF today, as proteins bring many of the key characteristics to a product, like flavor, texture, structure or medicinal value.

However, other types of molecules have the potential to be made as well- including fats, oils and chemical compounds. This means that products across many different industries could benefit.

Plant-based dairy alternatives made using PF will disrupt the dairy industry

Companies like Perfect Day and New Culture have attracted significant investment and attention from both consumers and the media, indicating that there is significant interest in Precision Fermentation products.

Additionally, several major dairy companies have also started to invest in Precision Fermentation technologies as a way to diversify their product portfolios and reduce their environmental impact. For example, Danone has formed a partnership with Perfect Day to produce plant-based dairy products, and Fonterra, New Zealand's largest dairy company, has invested in Motif Ingredients, a company that is developing dairy proteins using Precision Fermentation.

-min-1.png?width=732&name=Copy%20of%20Website%20imagery%20-%20Featured%20Image%201200x628%20(3)-min-1.png)

-min-2.png?width=732&name=Copy%20of%20Website%20imagery%20-%20Featured%20Image%201200x628%20(2)-min-2.png)

-min-1.png?width=732&name=Copy%20of%20Website%20imagery%20-%20Featured%20Image%201200x628%20(4)-min-1.png)