-min-4.png?width=1200&name=Copy%20of%20Website%20imagery%20-%20Featured%20Image%201200x628%20(1)-min-4.png)

By Taylor Hinds

The global energy system is undergoing a profound transformation. Falling costs and rapid advancements in wind, solar, and battery technologies are disrupting the incumbent fossil fuel-based systems, unlocking cheap, decentralized, superabundant clean energy for all regions that choose to adopt it.

Wind power was the first of these technologies to be widely adopted into national energy systems around the world, starting in the 1990s and taking off in the early 2000s. Though wind is now widely accepted as a viable energy generation technology, this was not always the case. Wind power is one of the oldest forms of energy generation available; people have been harnessing the wind to do work for thousands of years. Sail boats come to mind as the oldest example, followed later by early windmills that pumped water and ground grain.

So how did we get to where we are today? How did wind go from simply grinding grain on the farm, to lighting a few lightbulbs, to powering entire countries? Exponentially falling costs are half the story. For example, since the 1990s, the cost of building new wind capacity—the capex—has fallen 60% and the cost of generating electricity with this new capacity—the levelized cost of energy—has dropped 85%.

But for a technology to transform an industry, it also needs the capability to meet that industry’s demands at scale. If a technology is not good enough, it will not be useful, no matter how cheap it is...

Early experiments

The very earliest windmills only did mechanical work. Large cloth or reed sails harnessed the wind, which spun the axis and powered gears or shafts which, in turn, drove equipment like millstones and water pumps. They expanded through Europe and around the world, primarily being used for agricultural purposes until the Industrial Revolution in the late 1700s introduced steam and internal combustion engines—dramatically more effective ways to mill, pump water, drive machinery, and do other kinds of useful work.

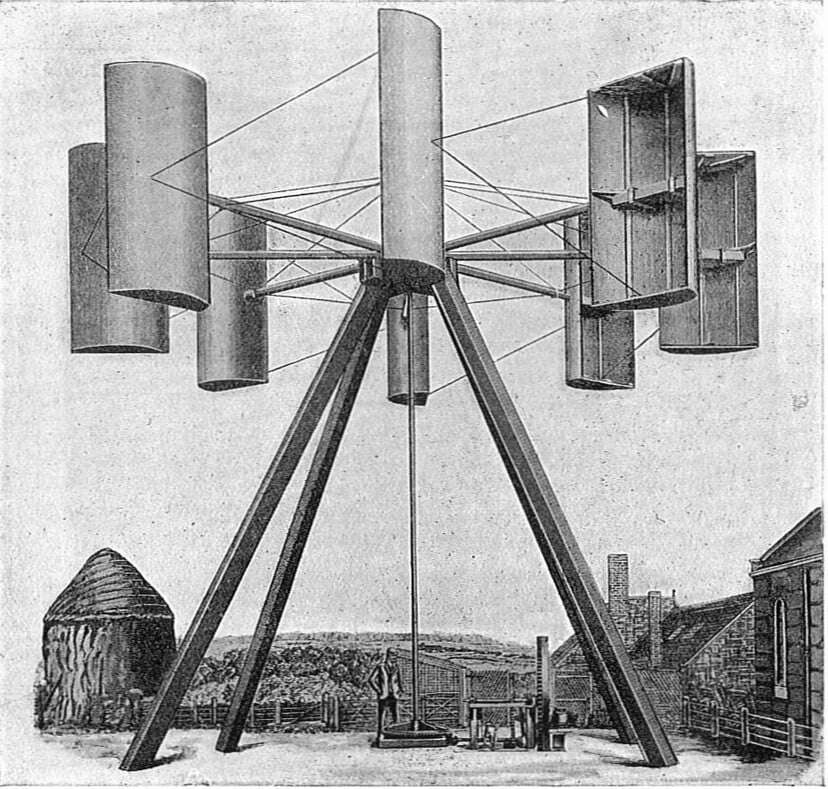

The first wind turbines to generate electricity were built nearly simultaneously in Scotland by James Blyth in 1887 and in Ohio by Charles Brush in 1888. The 1800s had been the century of harnessing electricity, and people all over the world were experimenting with different ways to generate and use electricity. These primitive electricity-generating wind turbines were, of course, simple and inefficient. Blyth’s first turbine powered only a few lightbulbs, but they proved without a doubt that the wind could be harnessed to produce electricity, at least on a small scale.

The path to utility scale

Electricity in the early 1900s, where it existed, was primarily generated by centralized coal, coal gas, and hydroelectric plants. However, there was a burgeoning interest in wind power during and after World War I as energy shortages sparked the desire for energy self-sufficiency, particularly in Europe.

Engineers around the world had been exploring different blade shapes, sizes, materials, and configurations to generate more electricity and make wind viable as a larger-scale generation technology. Turbines got taller and wider, and trended towards a standard horizontal axis design supported by steel lattice towers. Gearboxes were introduced in the 1920s to make turbines more efficient by converting the slow turn of the blades into higher speeds for the generator to produce the most electricity. They added mechanical complexity, and therefore more sources of breakdowns and faults, but enabled greater flexibility in the design and operation at varying wind speeds. Around the same time, the turbine blades went from sails to wings and became curved and aerodynamic in their design in the 1920s and 1930s, inspired by the nascent aviation industry.

The 1930s and 1940s saw turbines start to approach utility scale and produce a little more power. Mechanized yaw systems driven by electric motors were developed which allowed turbines to automatically turn to face the wind, allowing them to more consistently generate optimal energy. Around this time, turbines also transitioned from direct current electricity to alternating current which would allow them to be more compatible with the grid.

These early utility-scale turbines were neat, but they were still not viable sources of energy. They were one-of-a-kind proof of concepts that were expensive to build and maintain because they were mechanically unreliable and prone to breaking down. Energy generation was very intermittent as these early systems were fixed speed and could only work in ideal conditions, which affected their economic viability. One turbine, the Smith-Putnam wind turbine, which was a huge two-blade turbine for its time—generating 1 MW in 1941—broke down after just 1,000 hours of operation. It was never repaired due to wartime shortages; no turbine reached the same size for another 40 years.

With the 1950s came a breakthrough thanks to Johannes Juul and his three-blade, 200 kW Gedser turbine that inspired Danish design in turbines for many years to come. This turbine was still fixed speed, but it introduced a feature called stall control which helped to decrease production in high winds. This made turbines more resilient, much safer, and even more compatible with the grid. The Gedser turbine proved that wind power could be a meaningful, reliable, durable, safe and grid-compatible source of power at a relatively low cost. It also cemented Denmark as a leader in wind power development.

There was moderate interest in wind energy in countries like Denmark, Germany, and the United States from the 1950s to the 1970s but, in general, centralized electricity was king, and it became completely dominant in urban and rural areas. Oil-fired power plants, nuclear plants, and hydropower powered the grid, and few were worried about alternative sources of energy until the global oil crisis of 1973 changed the global sentiment.

Becoming viable

With new-found interest and funding in wind technology in the aftermath of the oil crisis, the average size of wind turbines increased dramatically, with rotor diameters growing from about 30–65 m to nearly 100 m by the late 1980s. Steel lattice towers now competed with taller, sleeker, tube-shaped towers that were introduced in the 1960s, which allowed the towers to reach heights of 40–50 m first, then beyond to 80 m by the 1980s. These improvements allowed the turbines to capture more energy and reach stronger and more consistent winds, which translated into greater power output.

Innovations during the heyday of computing and electronics in the 1980s were very important for wind turbines as engineers developed converters and inverters that incorporated power electronics into wind turbines. Power electronics were essential; they finally allowed turbines to deliver consistent power that was fully compatible with electrical grids. Prior to this, wind turbines would produce variable power due to the fluctuations in wind speed, which was largely incompatible with the standard grid.

Pitch control replaced the earlier stall control in wind turbines, which allowed the blades to adjust their angle based on wind speed, optimizing energy capture in varying wind conditions and improving efficiency. Variable-speed turbines replaced fixed-speed turbines, allowing turbines to adjust their rotational speed to match wind conditions, reducing stress on the mechanical components and increasing energy output. And finally, new materials like fiberglass made turbine blades lighter, stronger, and more resistant to weathering and warping than the wood and metal of older turbines.

These essential developments enabled the first utility-scale, grid-connected wind farms which were built throughout the 1980s. These farms were much smaller than the farms we currently have, with each individual turbine being much smaller and less powerful. The world’s first wind farm, built in 1981, had 20 turbines, 30 kW each for a total of 0.6 MW (subsequent farms built in California in the 1980s, for example, were larger than that). During this time, the governments of places like Denmark and California subsidized and provided tax incentives to their wind industries which helped drive innovation while the technology was still too expensive to be competitive.

Offshore and online

The 1990s saw the world’s first offshore wind farm, built in Denmark in 1991. It consisted of 11 turbines, generating 425 kW each, in shallow water off the coast of Denmark. Offshore winds are stronger and more consistent than winds over land, which presented the opportunity for more energy generation per turbine, but also required said turbine to be much stronger to withstand the conditions. Direct-drive turbines were brought back, as their mechanically simpler form can take more of a battering than those with a gearbox. Turbines started to get larger and more powerful and were equipped with sensors that could detect wind speed, vibration, and temperature to allow for sophisticated control over energy generation.

The 1990s was really when wind energy began to take off around the world, with several countries pulling ahead as early adopters and installing some real capacity. By 2000, Germany was producing almost 10 TWh per year, the United States 6 TWh/year, and Spain and Denmark about 4 TWh per year each.

Innovation from the software boom of the late 1990s meant that engineers could now monitor and control wind turbine performance remotely and in real time; this became standard in the early 2000s. This advancement meant that wind farms could operate more efficiently and with less downtime, which maximized energy output and reduced operational costs. Wind energy was able to achieve grid parity (some with subsidies, some without) with fossil fuels in many regions by the late 2000s/early 2010s—an important milestone that triggered exponential adoption in several of those regions.

In keeping with an established trend, the size and capacity of wind turbines continued to grow. Blades were reinforced with carbon fiber, which allowed the blades to reach lengths of over 50 m each—a rotor diameter of 100 m. Hybrid towers made of concrete and steel allowed for heights of over 100 m, and capacities reached 1–3 MW for onshore installations and up to 5 MW for offshore turbines.

By 2010 several countries were generating significant wind power, and it has only grown since then.

Today’s wind turbines

Today’s modern turbines are the culmination of 100 years of technological development in multiple different disciplines, and they are bigger and more powerful than ever before. Wind-generating capacity is now installed all over the world. It is an important part of the global electricity mix, making up about 8% total generation as of the end of 2023. China is the leader by far, generating more than 885 TWh per year.

Some of the key defining features of onshore turbines today include the characteristic white towers, made of steel or hybrid materials that, in 2023, were on average just over 100 m in height. The three aerodynamic blades, mostly made up of fiberglass that efficiently capture wind energy across a range of speeds and directions, are now on average 130 m in diameter. Onshore turbines are now on average 3.5 MW per turbine. For reference, a football field is 110 m long. These turbines are huge in every way and getting bigger every year.

Offshore turbines on the other hand, have gotten absolutely colossal. Minyang, a Chinese company, said in September that it had installed a concept 20 MW turbine with a rotor diameter of 260 m. They are not all nearly this large yet, but offshore turbines of over 10 MW with over 160 m diameter and over 100 m tall have been installed commercially. Floating platform technology, while still in the early stages of commercial deployment, is allowing offshore turbines to go farther and farther offshore, where they can access even better winds in places where the ocean floor is too deep to anchor.

Today’s turbines are also very smart and getting smarter. Advanced monitoring systems with sensors and AI-driven controls can provide real-time weather and logistical data, enabling predictive maintenance and minimizing downtime. Similar monitoring systems are also being deployed to detect animals, like birds and bats, that have a history of collisions with turbines. These systems can manage the blade speed and direction while the animals are passing to prevent collisions. Ultrasonic deterrents that cannot be heard by humans are also being developed and deployed to protect animals.

The integration and often collocation of wind energy with solar and batteries is important for the future of the energy system, and part of this is ensuring that wind energy can be used at many scales. Utility-scale wind is being installed more and more alongside solar and battery storage, but advancements in compact turbine designs, low-noise blades, lightweight materials, and vertical-axis configurations will contribute to the expansion of wind energy at smaller scales—particularly in residential and commercial environments.

Greater than the sum of its parts

The most important feature of today’s wind turbines is that they are able to be integrated seamlessly with solar and batteries at any scale. On it’s own, wind power can hardly be more than a supplemental form of electricity because of the inescapable fact that the wind itself is intermittent - it doesn’t blow all the time, and some regions have more than others. But an integrated SWB system elevates wind power to be the foundation of a global energy system that is far cleaner, cheaper and more abundant than any other energy system on the planet.

Alongside wind turbines, solar panels and battery energy storage have been improving in both cost and capability over the past hundred or so years since they were all invented. It is just now, in the 2020s that the convergence of all three makes it possible for SWB systems to be deployed around the world, at utility-scale quickly, and cost effectively.

SWB systems are greater than the sum of their parts. Solar and wind both rely on intermittent sources of energy - the sun and the wind, but these tend to be complementary. Often, the wind is blowing when the sun is not shining - such as at night, or in a storm and vice versa. Each on their own can leave gaping holes in energy generation, but together they generate much more consistently through the year. Battery storage is the final piece that comes in to smooth it out, by storing energy solar and wind when its available and releasing it when it is not. The key is that when building an SWB system, to take the region’s sun and wind resources into account and build enough generating and storage capacity to guarantee coverage for the most difficult periods of the year. When this balance is struck just right it means that these energy systems produce tons of useful, surplus energy during the rest of the year that will improve prosperity whether we are looking at a whole country, a village or a single household.

The dramatically increasing scale, capability and versatility of wind turbines (and solar panels, and batteries) makes this possible now, when it was not before. Innovation has taken the humble wind turbine from lighting just a couple lightbulbs in someone’s front yard to swinging blades the size of a football field over the ocean to power an entire country. These modern powerhouses, in combination with the equally impressive modern solar panels and batteries have the capability to transform the global energy system by disrupting incumbent fossil fuels. And they will do so faster than anyone expects.